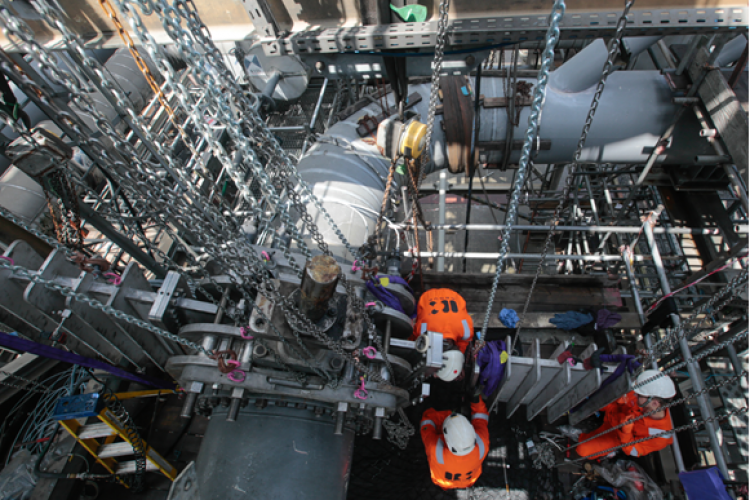

A purpose built 36” 150# AOGV has been successfully deployed to isolate on a live flange pair in the flare line at a major LNG facility. The purpose of the isolation was to facilitate a changeout of a 36” butterfly valve that had been stuck in an open position for a prolonged period of time. The valve needed to be replaced with no disturbance to the operation and throughout. A positive isolation blind was inserted by use of the AOGV in the flange pair upstream of the valve, the existing valve safely removed, and a new valve installed. The blind was then removed, and the system brought back to normal operation. The main flare was operational through the entire operation. The AOGV was designed, fabricated, tested and certified for cryogenic service and is so far the largest AOGV built and the first application on the African continent.

"Another great example of how the disruptive AOGV mechanical isolation tool can help our customers perform maintenance without production downtime” says Svein Tore Milwertz, IK-Groups AOGV Operations Manager. If you'd like to know more, visit AOGV.com