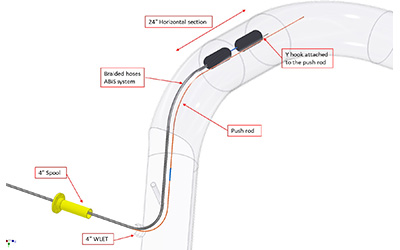

IK-Group was to asked to provide a solution to isolate the 24" Line 24"-PT-01-002-P3D from hydrocarbons during the welding operation of the new 4" spool. We proposed a solution for isolating the 24" line which consisted of installing a 24" ABiS™ set on the upper side of the 4" branch, to create a double isolation barrier with monitoring of hydrocarbons between the barriers, and a single isolation barrier with by a pass line on the lower side of the 4" branch, pending space limitations.

- Urgent delivery, custom-built

- DBB gas isolation system DBB isolation set including real time logging and LEL verification and high LEL alarm warning system

- Possibility to retrieve the 24" Isolation system via a 4" branch