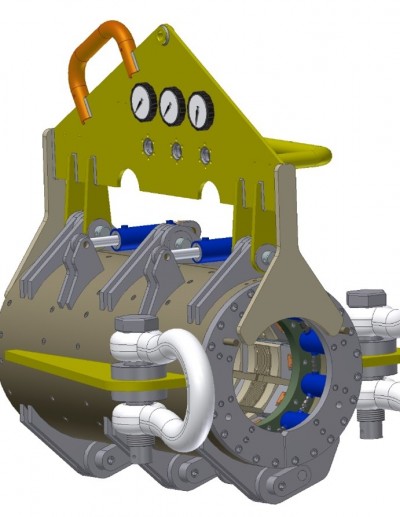

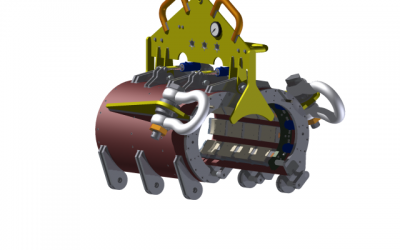

IK designed and delivered 5 off ROV operated Holdback Clamps for the Thunder Horse “buttered weld defect” repair project.

The equipment delivered were all rated for the 2000 meter of water at the location. Requiring a proper test program documenting the high water pressure combined with the advanced hydraulic functions to be run.

The Holdback Clamps were used for securing the Steel Catenary Risers ( SCR ) when they were cut at the PLET locations. The SCRs were then lifted up to the surface for repair of welds that had been found cracking.

The Holdback Clamps were secured on to the outer surface of the SCR and then connected to a suction anchor by a chain / wire system. The 5 holdback clamps covered three different dimensions, 8”, 10” and 12” SCRs.

The Holdback Clamps were “biting” onto the Thermotite (3LPP) coated lines by use of a wedge and teeth system being hydraulically activated.

The clamps were delivered on planned time and cost and later used as planned for the repair operation.

The client was happy, problem free repair of a relatively complicated repair scenario

Christian Knutsen, CTO