The patented AOGV mechanical isolation tool is a revolutionary technology. Put simply, it allows you to isolate a pipe segment whilst keeping the rest of the facility running – maintenance without cashflow shutdown is totally achievable! This week, the AOGV team are in North America showcasing the new technology to plant and facility operators, contractors and service companies.

Whenever process plant equipment or systems are required to be taken out of service for major maintenance, repair and modification, positive mechanical isolations are provided between the process plant equipment or system and any potential hazardous energy source.

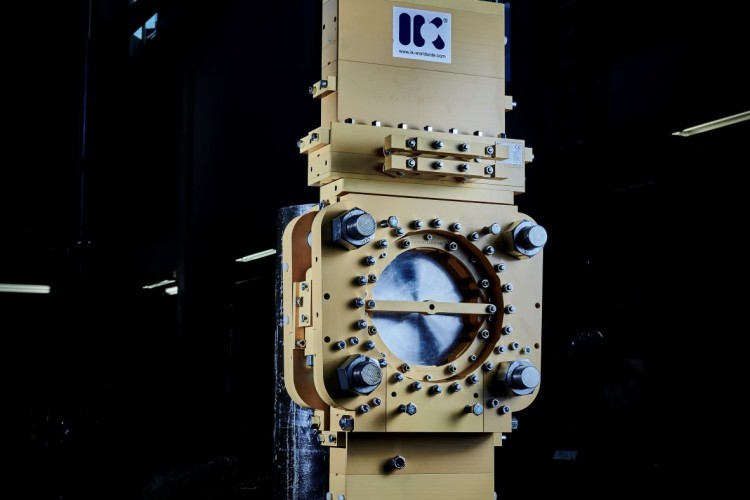

The AOGV is used to install an isolation spade, also known as a pipe blind or blanks, on a live flanged connection. It can also be used to close or open a spectacle blind or replace a spacer with a line blind while the system is still pressurized. This field proven technology reduces downtime, removes the need for drainage, venting, purging and flushing and it increases your maintenance flexibility.

The AOGV is used to create a zero-energy zone where inspection and maintenance work can be performed safely and efficiently, plus it leaves no lasting impact to the process plant. Once the operation is complete, the flange pair is returned to its original pipe spec state with a new gasket, bolts, and nuts.

The AOGV is versatile – typical AOGV applications include:

- Repair and modifications of parts of process facilities

- Retrospective installation of equipment

- Installation, repair, or replacement of valves

- Emergency plant and piping repairs

https://www.youtube.com/watch?v=f8SBTAOq2ZA

For more information contact VP AOGV Rune Sele here.