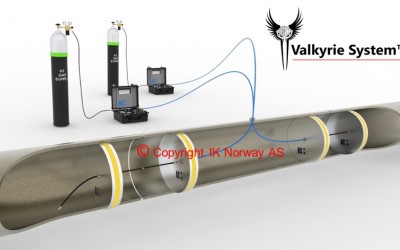

Due to the use of long flangeless lengths of piping and multiple bends, traditional back-gas equipment would be challenging to remove after welding and would in most cases require flushing for removal. With the use of IK’s Valkyrie System™ one can avoid the traditional tasks of flushing, hydrostatic pressure testing and drying of the pipelines after the welding operations, thus significantly reducing the commissioning time and cost.

IK’s Valkyrie System™ is comprised of three different back-gas system solutions to cover all the pipe sizes. The solutions allowed for extremely efficient welding operations due to sophisticated purge methods. All the Three Valkyrie systems removed through a 1-inch Threadolet.

IK’s Valkyrie System™ products use an advanced gas purge monitoring & flow control unit. All operations are carefully planned, and all products are custom built in-house at IK-Norway. All services are performed by experienced and certified IK-Norway personnel.

> Extreamly efficient purging of inert gas

> Excellent weld quality

> Backgas products up to 24" can be removed through 1" Threadolets

Aibel AS