With ONS fast approaching, we are filled with anticipation and thrilled to invite you to visit us at the IK Group stand.

It has been a year-long planning process focused on offering an outstanding experience to our clients and friends that showcases this new phase of IK Group. We are so excited to finally see our idea come to life. With our new brand identity already revealed, it’s now time to share the future we envision for our companies and brands.

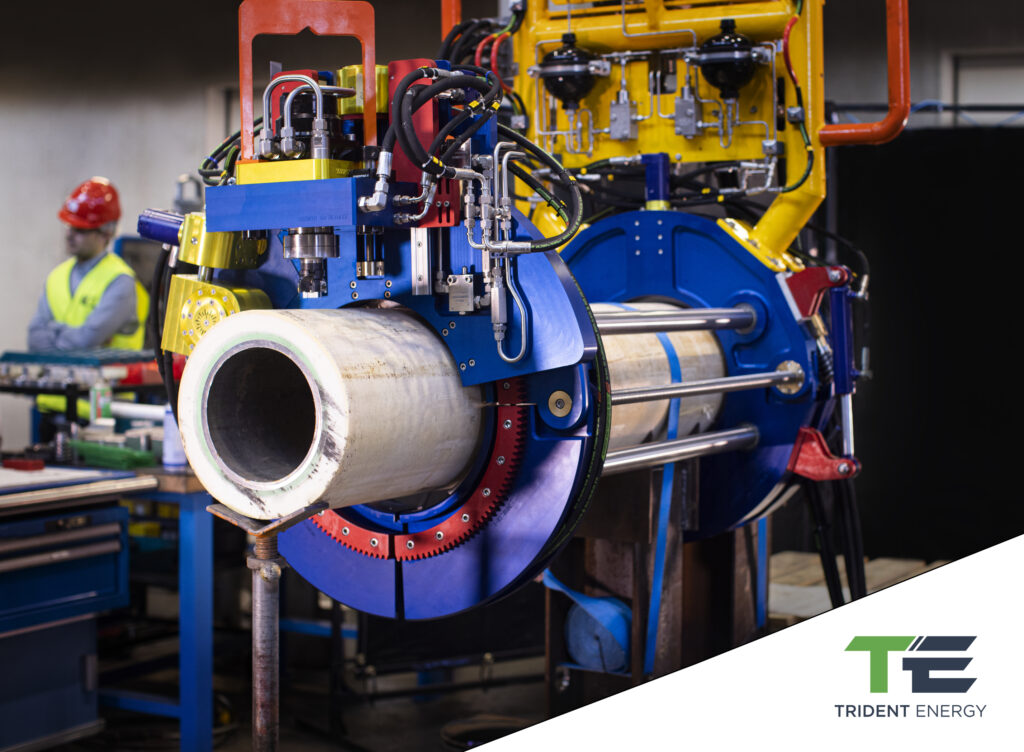

This year, the IK Group stand will be centrally located in Hall 7, carefully designed as a dedicated space for business meetings and networking. Here, our clients, partners, and friends can meet representatives from all our business areas and explore the wide range of services and products that define our brilliant engineering.

Be sure to visit us for a comprehensive overview of everything we, together with our business areas, Izomax, IK Subsea, IK Trax, IK Topside, IK Engineering, and Norclamp, have to offer.